Somehow getting a toaster oven is not considered appropriate by some administritive staff so I don't want to bother. I thought about getting it but only for my personal use, not for my project on university grant money. The design is neat since it is one box while other tutorials have dozens of steps and messy wires. I thought about Leaded paste but thought I should stay away from it if I can so anyone in Europe could make purchases on assembled boards without trouble. R276 looks good, need 240C-245C for a peak, 473F, quite a bit hotter. Look up the temp profiles for lead-free paste here Leaded paste needs about 400F (205C) as the high temp, need 4 elements to ramp up. Haven't reflowed in it yet, but have used it for curing epoxy, 2 hours at 150F for the thermally conductive epoxy we used.) (I have a new Black & Decker 4-element oven (1500W seems to be the key to look for) that we got at Target on sale for $50. Edit your board to remove dimension line and things like corner mounting holes and make Gerbers, then the paste layer will be minimized in size resulting in lower cost.

Table top reflow oven free#

Nothing expensive tho, just an old Sears Kenmore 4-element toaster oven we had in the basement (under cabinet toaster oven had taken its place to free out counter space). I manually control the temperature (as I haven't gotten around to assembling an automated controller). I do bench top (kitchen countertop) all the time, but with lead solder, Kester EP256. I've made some jigs to save time for the future. Thru-hole components are another half hour. If I could reflow, then I could save maybe half the time or even more. Using flux and wire solder, I cut it down a bit but still too much time. It takes about an hour of my time to assemble all smd components using wire solder, an iron and solder wick and inspect the board.

My board has a number of smd IC and chip resistors etc. Without a stencil the solder paste amount is too hard to control. I have a hot air rework station so I could try it again once I get a stencil for my board. I won't have money for other stuff such as a Weller station etc. Any suggestion for inexpensive hardware? I can certainly get this oven if it is decent.

Table top reflow oven manual#

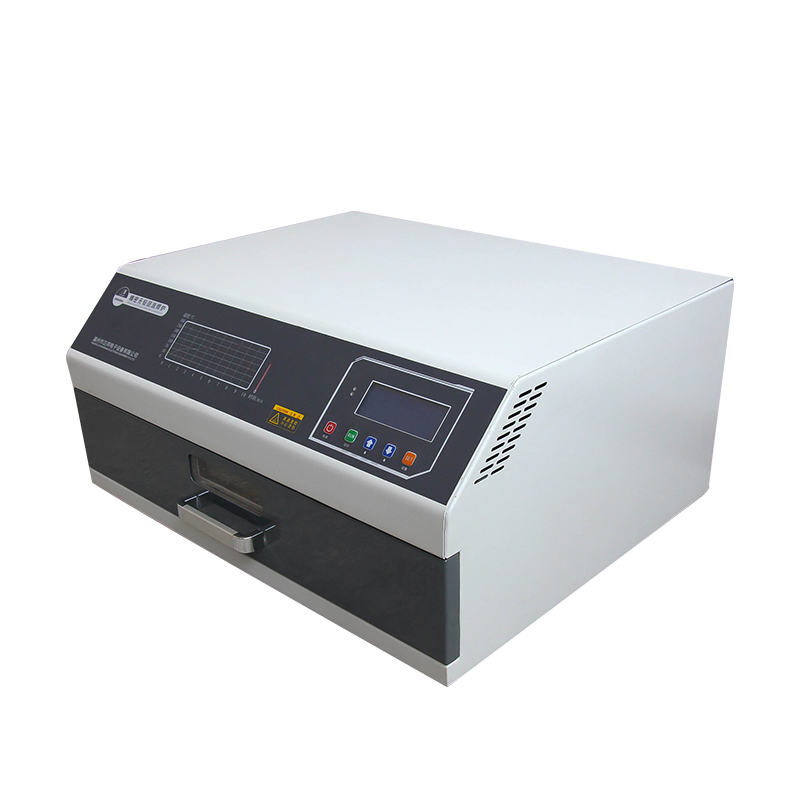

The least expensive one that works with lead-free solder is this one:ĭoes anyone have experience with it? The manual seems to be a very poor translation job. I've looked at some entry-level IR ovens around $200 (T-962) and they don't provide even enough heating at the higher temperature for lead-free solder paste. I am considering purchasing some reflow devices to do lead-free solder paste for my devices.

0 kommentar(er)

0 kommentar(er)